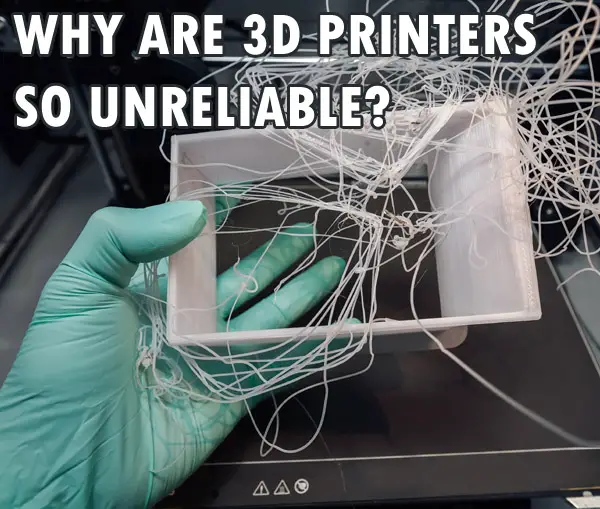

Reliability is crucial in the field of 3D printing. 3D printing involves creating objects layer by layer, and any errors or problems in the process can result in an unsatisfactory print.

So, why are 3D printers so unreliable?

Calibration issues, wrong material selection, incorrect slicing settings, and incorrect bed leveling are some of the factors that can cause unreliability in 3D printers. 3D printers require proper calibration to function properly. If the machine is not calibrated properly, it can lead to problems with the quality and accuracy of the prints. Also, 3D printing devices require regular cleaning and maintenance to keep them working properly.

What are the factors that affect the accuracy of 3D printers?

Warping and shrinkage

Many factors can cause 3D prints to warp. The distortion of a part from its original shape is known as warping.

Much of 3D printing entails extruding liquid filament (melted material) from a heated 3D printer nozzle onto a heated print build plate or bed. The bed is a flat surface on which the printer creates an object.

The liquid turns into a solid when it comes in contact with the print bed. During phase shifts, 3D printing filament keeps its mechanical characteristics. They do, however, experience growth and contraction.

These are the ways that warping shows in 3D prints:

- Warped 3D prints are most obvious at the base layer, where they are exposed to a broad range of temperatures from the succeeding layers.

- Other layers may also warp due to the pull-up effect of the following layers as they cool on the cold layers.

- Warping can also be caused by a solid base layer that sticks to the 3D print bed.

What causes the 3D print to warp?

Below are some causes of warping you should be on the lookout for during 3D printing.

- Printing too fast

The following can result from printing too quickly and result in 3D prints that are warped:

- Plastic filament won’t lay evenly; it will curl.

- Rapid printing can also cause the layer to cool suddenly. Additionally, it will weaken the plastic layer.

- Wrong slicing settings

The slicer software chooses the best route for the 3D printer to follow in order to produce the desired object. This path is calculated depending on several factors, such as the preferred resolution, the kind of material being used, and the orientation of the object. If any of these settings are wrong, it can cause the object to become out of shape during 3D printing. Incorrect slicing settings can also make sections of the item come loose from the print bed. Additionally, the finished object may warp or be inaccurate as a result of these detachments. Therefore, before starting a print project, it is vital to make sure that all slicing settings are accurate.

- Incorrect print bed adhesion

The first layer of a 3D print needs to correctly attach to the print bed. If this doesn’t happen, the very next layer may contract and lift the preceding layer. This can then result in 3D prints that are distorted. There are several reasons why a bed doesn’t adhere properly:

- Dirty 3D print bed

- Inadequate extrusion

- Incorrect height of the nozzle

- Incorrect application or lack of adhesive

- Incorrectly leveled beds

- Temperature variations

The heated plastic thread expands and contracts during extrusion. Temperature variations can shorten or lengthen the expansion. A warped 3D print could result from the sudden cooling of the extruded filament.

This is the most frequent cause of 3D print warping and it happens because of improper 3D printing filament selection, inadequate cooling fan speed, non-uniform cooling, and inadequate airflow.

Materials used

The materials you use affect 3D printing accuracy in some ways. In many instances, improving particular material properties will necessitate compromising reliability. A regular SLA resin, for example, will result in components with better dimensional accuracy compared to a flexible resin.

You should use common printing materials like Ultem and Nylon for parts where high accuracy is essential.

Dimensional accuracy

The 3D printed parts should be dimensionally accurate if you are producing components that need to fit together or if you are producing vast assemblies.

Various factors can influence this accuracy like first-layer nozzle alignment, filament quality, and over or under extrusion. The success of your 3D prints depends critically on a 3D printer’s accuracy. It establishes how well the first layers can be laid down.

Calibration

Calibration can also affect the accuracy of a 3D printer. The 3D printer must be calibrated in order to create prints that adhere to the desired specifications. It needs to have many parts adjusted, such as the 3D printer filament type, the extruder, and the stepper motors.

The following are just a few benefits of calibrating your 3D printer:

1. A better grasp of your device

Calibrating your printer can help you develop a better grasp of your 3D printer. if you learn how to adjust it correctly, you’ll gain a deeper understanding of how your 3D printer operates and how to use it efficiently.

2. Increased control over the printing procedure

You can adjust the settings to get the desired print each and every time.

3. Improved efficiency

When calibrated correctly, your 3D printer can print more quickly and precisely. Your prints will be completed more quickly, allowing you to proceed to other tasks.

4. Less waste

When printing without calibration, the printer is unable to properly regulate the material flow, which can cause wastage or overuse. Through calibration of your 3D printer, each drop of filament will be utilized efficiently with no wastage.

5. Better print quality

If your 3D printer is calibrated properly, your prints’ quality will significantly improve. They won’t just be more precise; they’ll also be finished more smoothly.

Design

The accuracy will also be impacted by the item’s size. The dimensional accuracy of smaller objects is typically much better than that of bigger items. This is because there is less space for mistakes and they are simpler for the 3D printing device to print.

How to Fix 3D Print Warping?

Control the temperature

Controlling the temperature of the printer and its surroundings is one method to stop warping. Given below are a few steps to take:

1. Modify the cooling

Modifying the cooling for 3D printing can help to minimize warping by enabling the material to cool at a controlled rate.

The majority of 3D printers have a cooling fan that aids in keeping the material cool while it is being produced. Changing the fan’s direction and speed can help regulate the rate at which the material solidifies and cools, which can lessen cracking and warping.

2. Print in a fully enclosed print chamber

Printing in a closed chamber can help to decrease warping in 3D printing by keeping a constant temperature around the material being printed and the machine. A printing enclosure aids in preventing temperature changes that could cause the material to cool at varying rates, resulting in warping.

3. Use a heated print bed

Using a heated print bed is a great way to minimize warping in 3D printing. A heated bed aids in temperature control and can stop the material from cooling and contracting too rapidly, which can result in warping.

Below are some tips for using a heated print bed:

- Warm the bed: Be sure to pre-heat the build plate to the proper temperature for the material you’re going to print. This will help to ensure that the material will be at the ideal temperature when it is placed on the bed.

- Use the proper bed temperature: Different materials require varying temperatures, so make sure to adjust your build plate’s temperature appropriately.

Improve 3D printer bed adhesion

Good bed adhesion is essential for avoiding warping during 3D printing. Here are some of the ways to improve 3D printer bed adhesion.

1. Adjust the level of the build plate

Some 3D machines feature an auto bed leveling system, which uses a sensor probe to measure the height of the build plate at different points and adjust the build plate height as necessary. However, if your 3D printer does not have this feature, you can physically level the build plate using the machine’s adjustment screws.

An unlevel bed frequently causes print quality problems, such as ruined prints or warping, which results in a loss of resources, such as time and material.

2. Clean the build plate

Your build plate needs to be thoroughly cleaned to get rid of any adhesive left over from previous use. Doing so will prepare the build plate for the next print, and bed adherence will be enhanced.

3. Use the right adhesives

Using the right adhesive, such as hairspray or glue sticks, will ensure the item remains attached while it cools down. This will lessen the possibility of warping.

I hope this article was helpful in understanding why 3d printers can be unreliable and some solutions to make them more reliable. Click the following link to learn if 3d printers are hard to use.